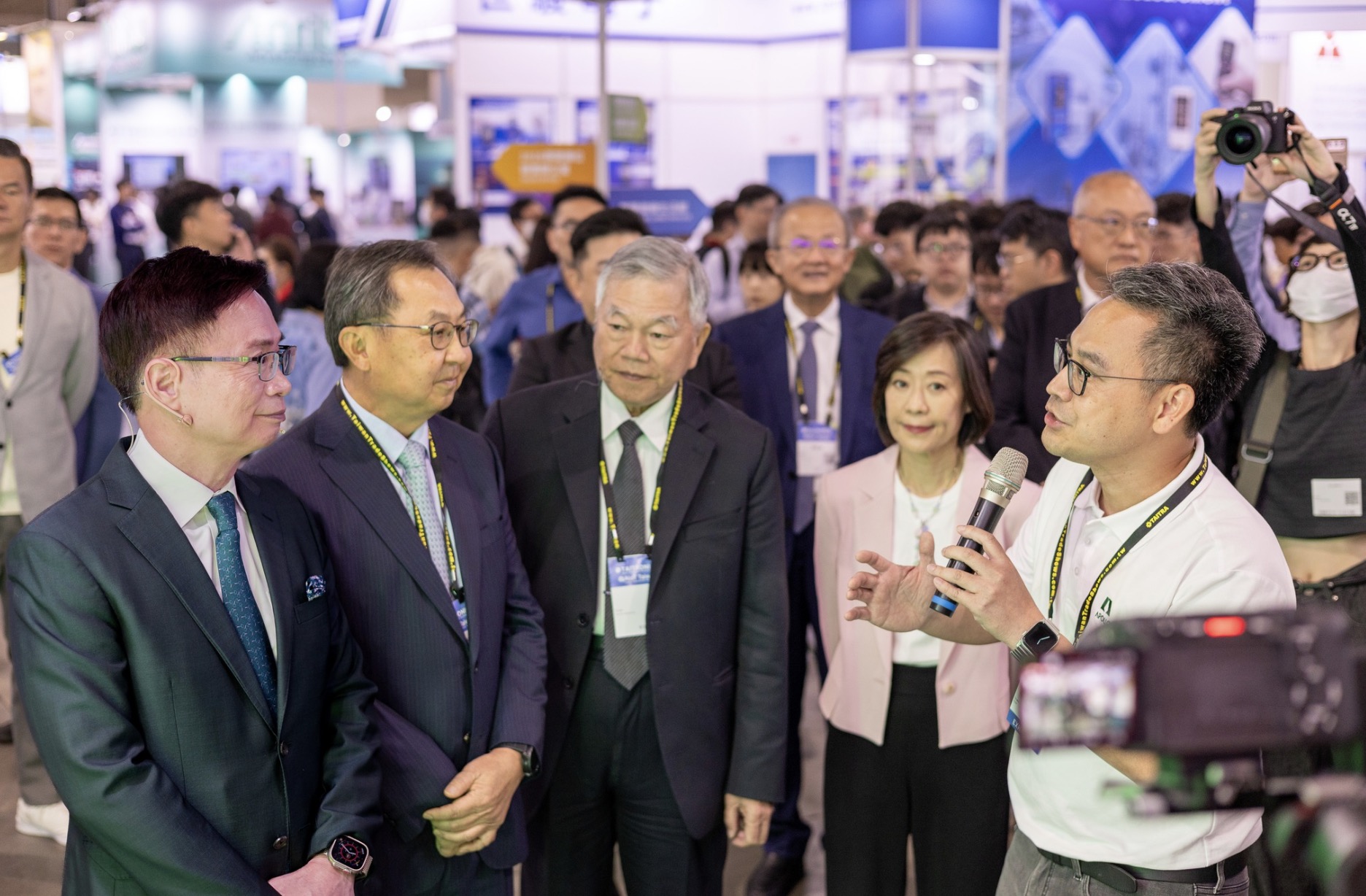

From AI-powered robotics to edge computing and smart mobility platforms, TAITRONICS & AIoT Taiwan 2025 spotlights Taiwan’s evolution from hardware manufacturing to full-scale AIoT solution integration.

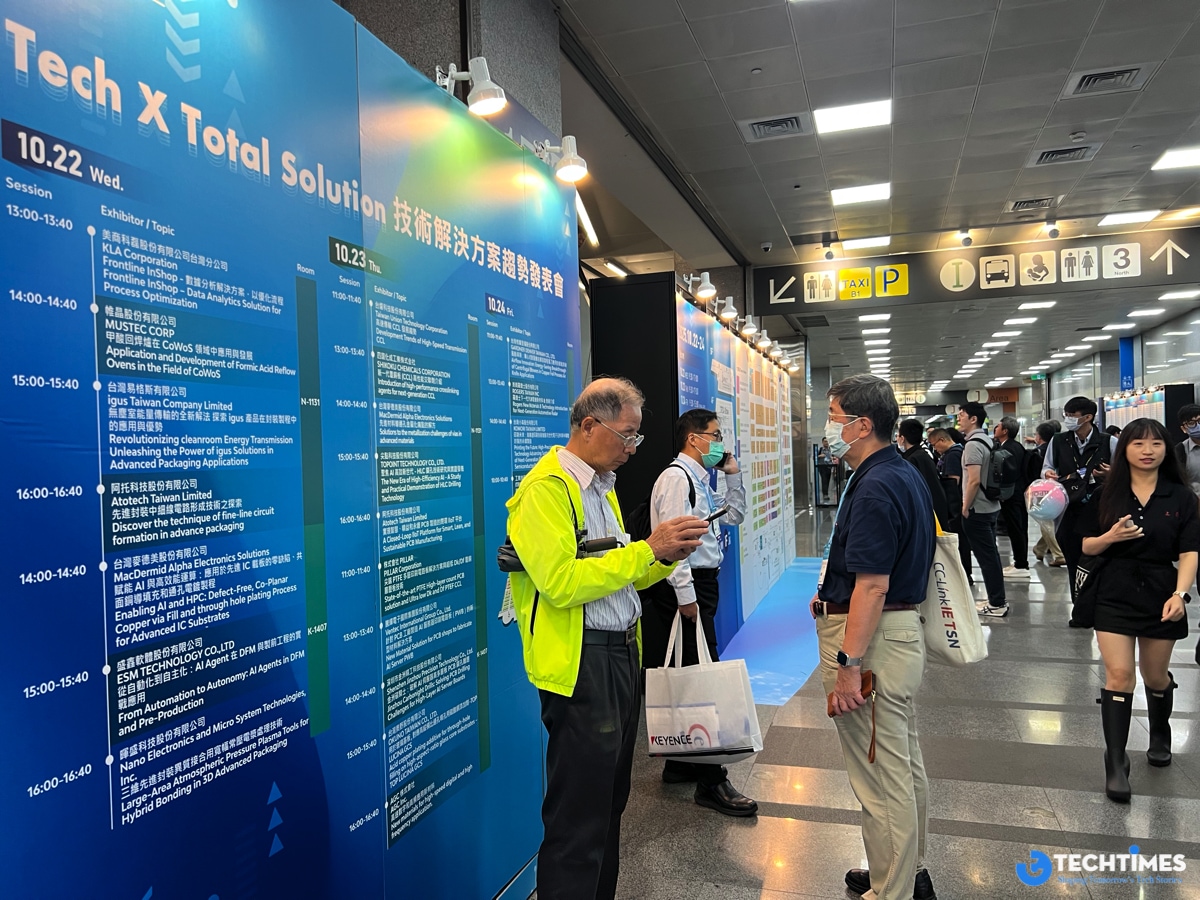

TAITRONICS & AIoT Taiwan 2025 — hosted at Taipei Nangang Exhibition Center from October 22–24—has opened with a clear message: the island’s ICT supply chain is moving beyond components into fully integrated AIoT solutions that combine sensors, edge compute, connectivity and domain AI. Over the two days since the show opened, exhibitors have focused on commercial-ready offerings for industrial automation, smart cities, mobility and datacenter/edge deployments. This report synthesizes the most newsworthy product reveals and demos from the exhibition floor and the official exhibitor feeds.

Mobility & mapping: navigation stacks that behave like platforms

One of the attention-grabbing announcements came from iNavi Systems, which used its TAITRONICS presence to highlight a next-generation navigation solution built on TomTom’s Orbis map data. The offering positions mapping not as a standalone feature but as a contextual data layer for logistics, driver assistance and localized services across APAC markets. Demoed features include precision POI handling, real-time traffic overlays, and localized routing logic tuned for Taiwan’s dense urban corridors—capabilities aimed at fleet operators and city mobility managers rather than only in-car consumers. The iNavi–TomTom pairing underscores a broader trend at the show: map and traffic data are now integral inputs to AI-driven mobility services, not just passive navigation aids.

AI-powered inspection and production monitoring

Manufacturing-grade AI found a lot of floor space. Multiple Taiwanese suppliers and system integrators demonstrated automated optical inspection (AOI) systems augmented with deep-learning models to detect micro-defects across PCBs and SMT lines. These AI-driven AOI booths highlighted faster inference at the edge, model retraining workflows and integration hooks to MES/ERP systems—reducing false positives and minimizing manual rework. Several vendors also showcased RFID-based traceability stacks that pair high-speed readers with cloud dashboards to provide per-lot tracking, predictive maintenance alerts and automated compliance reporting—capabilities pitched to EMS (electronics manufacturing services) and contract manufacturers.

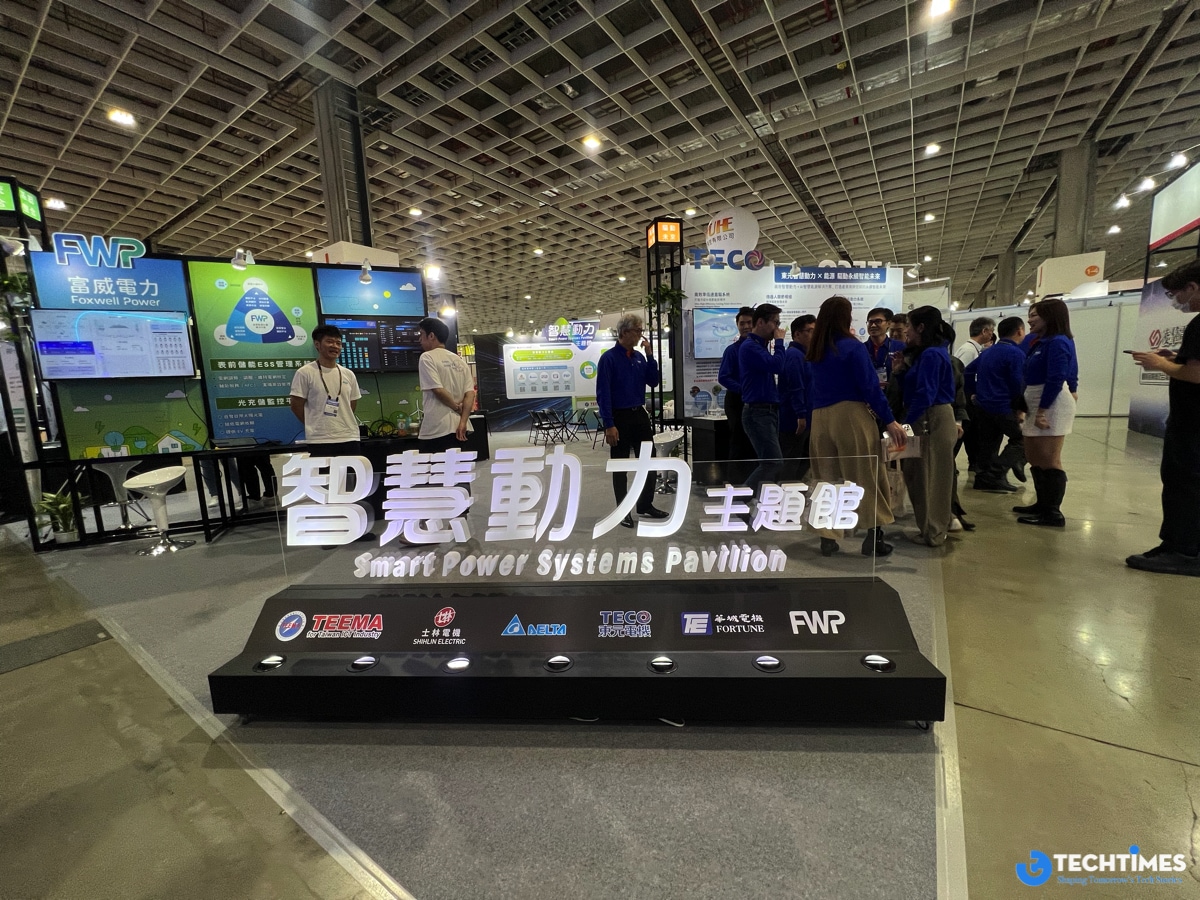

Edge infrastructure and power solutions for AIoT devices

A recurring theme across power- and component-focused booths was practicality: smaller form-factor power supplies, DC-DC converters optimized for wide input ranges, and medical/industrial-grade power modules that meet tighter EMC and thermal specs. These components are targeted at gateway nodes, telecom edge servers and battery-powered sensor clusters where efficiency, thermal headroom and regulatory compliance matter. Several exhibitors emphasized ruggedized designs and compliance with international safety standards, addressing a common barrier enterprises face when deploying sensors at scale. The emphasis on power reflects the show’s pragmatic shift from prototype modules to deployable system architectures.

Robotics and warehouse automation: applied AI for throughput gains

Robotics vendors used live demos to make a simple point: AI is slowly making autonomous material handling practical at scale. Cobots with modular end-effectors, AMRs (autonomous mobile robots) with improved SLAM and visual navigation, and orchestration platforms to coordinate fleets were all present. Several vendors showcased pick-and-place improvements using vision models trained to recognize varied part geometries and deformable items—critical for e-commerce and contract assembly lines. On the software side, companies emphasized integration with existing WMS (warehouse management systems) to shorten onboarding cycles for enterprise customers. The showcased solutions focus on improving throughput while lowering operator upskilling needs.

Sensors, environmental monitoring and plug-and-play telemetry

The sensor segment featured a mix of specialist hardware and turnkey telemetry stacks. Exhibitors displayed low-power gas and particulate sensors, vibration and acoustic sensors for predictive maintenance, and multi-parameter sensor nodes designed for agriculture and facilities monitoring. What stood out was the packaging—many vendors now ship nodes bundled with connectivity (LoRaWAN, NB-IoT, LTE-M) and cloud connectors, so a proof-of-concept can be live in days rather than months. This “deployment acceleration” ethos was a practical throughline for buyers seeking rapid ROI from pilot projects.

Datacenter, security and “trust” at the edge

With edge inference and local AI workloads growing, several companies showcased compact servers and AI inference appliances designed for edge datacenters. These units prioritize energy-efficient accelerators, integrated thermal solutions, and hardware-rooted security such as secure boot and device attestation. Vendors highlighted end-to-end device identity and certificate management as critical for large-scale IoT rollouts—reflecting increased buyer focus on firmware integrity and supply-chain security. The presence of these solutions signals industry readiness to move critical workloads closer to data sources while maintaining enterprise security hygiene.

International startups and ecosystem breadth

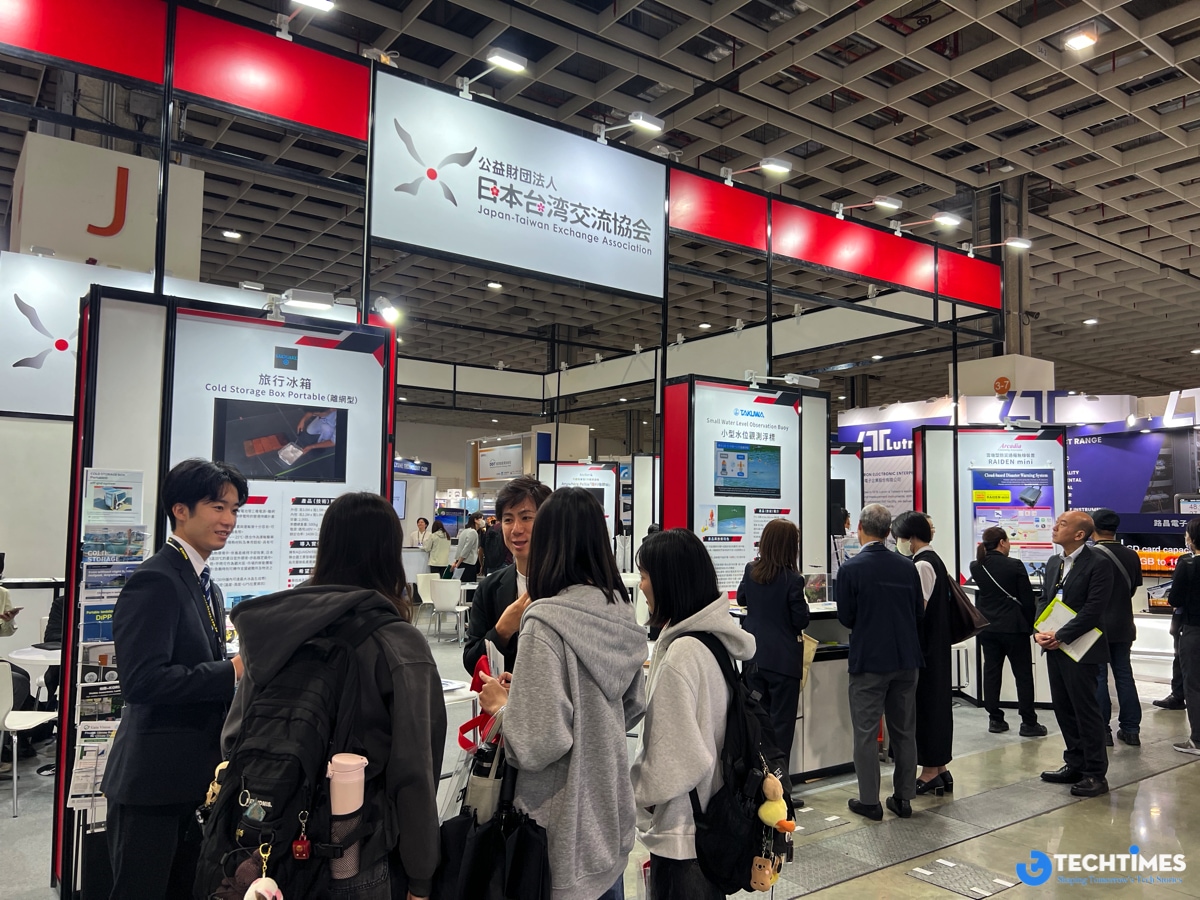

TAITRONICS attracted an eclectic mix of international startups alongside established Taiwanese OEMs. Delegations and smaller booths from Europe, Korea and even Kosovo presented modular edge stacks, logistics telemetry services and domain-specific analytics. This international participation added a cross-pollination effect: buyers could compare mature, Taiwan-built modules with agile, cloud-centric startups in the same aisle. The overall impression was of an increasingly globalized AIoT marketplace centered in Taiwan’s manufacturing ecosystem.

What this means for APAC adopters

Three takeaways are evident from the first two days at TAITRONICS & AIoT Taiwan 2025. First, mapping and mobility data are becoming platform services that contextualize logistics, urban planning and safety systems. Second, AI is now being operationalized at the edge—AOI, robotics and telemetry systems are shipping with inference capabilities and integration hooks that shorten time to production. Third, the component market is maturing: buyers can now assemble certified, efficient power and compute stacks with pre-built cloud connectors, reducing deployment friction for enterprises.

For companies in APAC planning pilots, the show suggests an operational playbook: prioritize integrated stacks (hardware + connectivity + management) over bespoke integration, insist on device security and lifecycle management, and evaluate mapping/traffic data as a strategic input for mobility-related deployments. TAITRONICS’ emphasis on “AInnovation Now” captures this pragmatic, production-ready spirit.