Bestyield, a subsidiary of Gigabyte, embraces the Mottainai philosophy and circular economy to transform electronic waste into value, extending device lifecycles, reducing 91,000 tons of CO2 through repair, reuse, and recycling, and showcasing its innovations during a TechTimes delegation visit at APCER & Hotspot 2025.

In an era where the digital landscape evolves at an unprecedented pace, electronic waste (e-waste) has emerged as one of the most pressing environmental challenges. With millions of tons of discarded electronics piling up annually, the need for sustainable solutions is critical. Bestyield, a subsidiary of Taiwan’s hardware giant Gigabyte, is leading the charge by integrating the Japanese philosophy of “Mottainai”—a call to avoid waste and maximize resource use—with a robust circular economy model. With over three decades of expertise in printed circuit board (PCB) repair and equipment maintenance, Bestyield transcends the role of a traditional repair company to become a pioneer in sustainable technology. This article delves into how Bestyield transforms “waste” into value, creating a triple-win scenario for the company, its clients, and the planet, with a spotlight on its showcase during the TechTimes delegation visit at the Asia-Pacific Circular Economy Roundtable & Hotspot 2025 (APCER & Hotspot 2025).

The Genesis and Global Reach of Bestyield

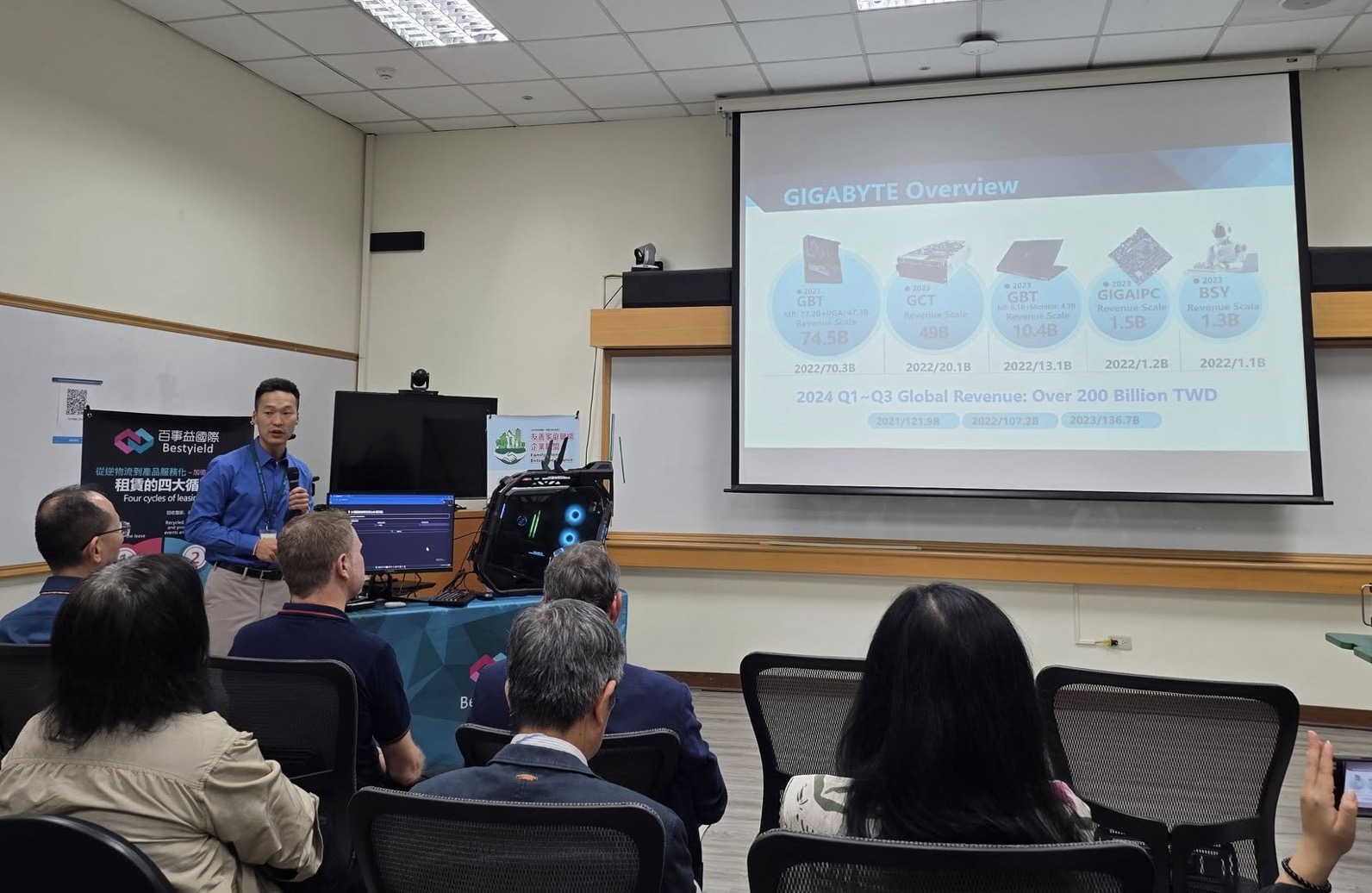

Founded in 2001 as part of the Gigabyte ecosystem, Bestyield began as a specialized provider of PCB repair services but has since evolved into a comprehensive end-to-end systems integrator. Today, the company boasts a formidable global presence, operating over 100 local facilities and more than 1,000 franchise partners across the world. With a workforce exceeding 8,000 engineers and staff, Bestyield is a powerhouse in the tech industry. The Gigabyte group reported a combined revenue of 275 billion TWD (approximately $9 billion USD) in its latest fiscal year, with Bestyield’s sustainable services playing a pivotal role in this success.

Bestyield’s scope extends far beyond repair. The company offers a full spectrum of services, including technical consulting for complex data center projects, post-sales maintenance, and advanced logistics solutions. As an official Apple Independent Repair Provider and the first authorized repair partner for Microsoft Surface devices, Bestyield upholds stringent quality standards, supported by specialized technical training, cutting-edge quality analysis, and efficient supply chain management. Its G+ Refurbished Outlet Stores provide consumers with access to affordable, high-quality refurbished products, ensuring that device lifecycles are extended without sacrificing performance or user experience.

The company’s global footprint is impressive, with operations in over 85 countries, including key distribution hubs in Germany (serving the EMEA region), North and South America, and a headquarters in Taiwan, complemented by regional offices in China and India. A recent milestone was the inauguration of a state-of-the-art, fully automated facility in Los Angeles, California, which enhances Bestyield’s capabilities in smart manufacturing and repair, reinforcing its commitment to innovation and sustainability.

Mottainai: A Philosophy of Resource Reverence

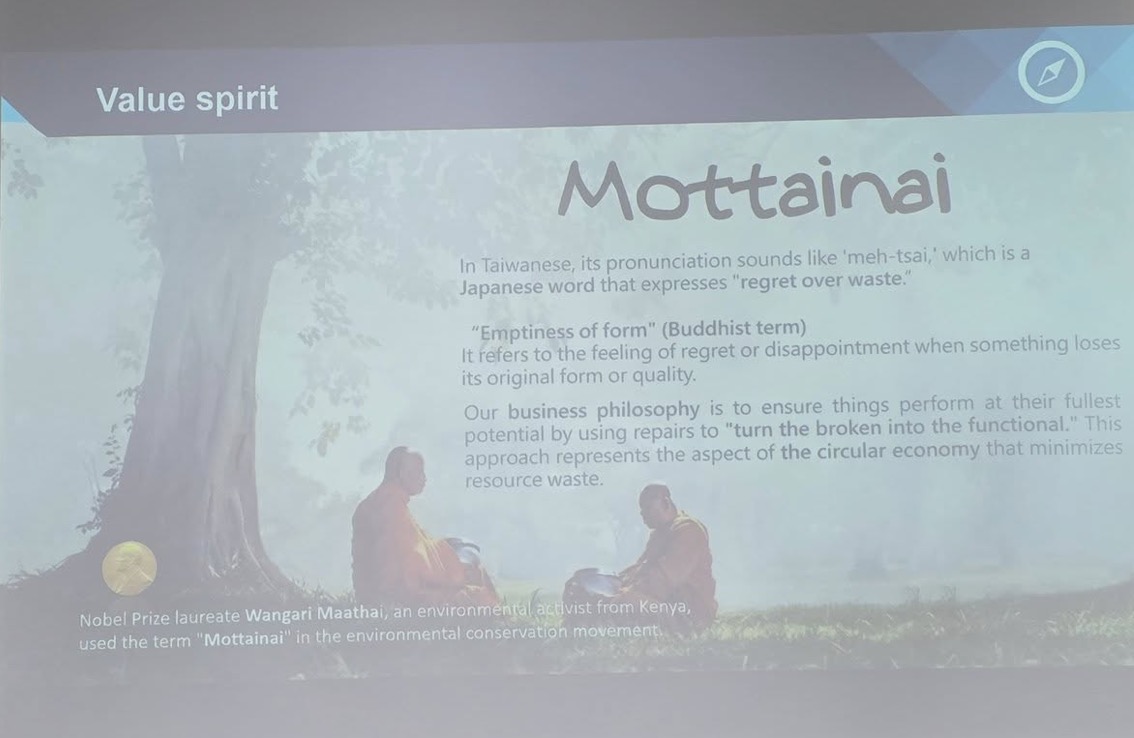

At the heart of Bestyield’s operations lies the Japanese concept of “Mottainai,” which translates to “what a waste.” More than a catchphrase, Mottainai is a deeply ingrained philosophy that guides Bestyield’s mission to minimize waste and maximize the value of every resource. In the context of the tech industry, where e-waste contributes significantly to environmental degradation, Mottainai inspires a holistic approach to resource management. Bestyield’s commitment to “repair, restore, and repurpose” ensures that every device and component is utilized to its fullest potential, transforming what might be discarded as waste into valuable assets.

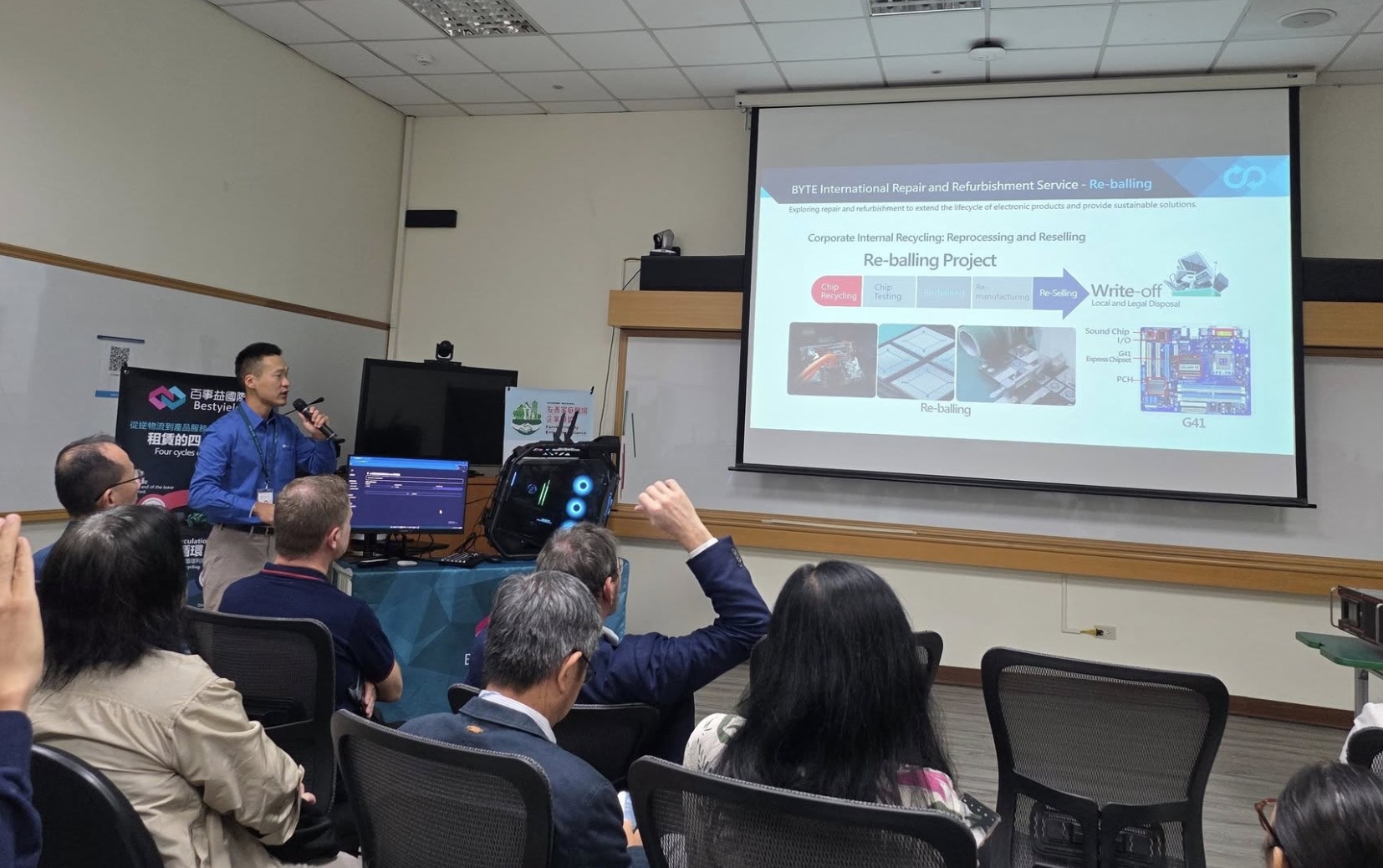

A standout example of this philosophy in action is Bestyield’s “reballing” process for integrated circuit (IC) chips, particularly those in motherboards, which account for 80-90% of a device’s value. By meticulously testing CPUs and restoring associated components, including the PCB itself, Bestyield can revive devices, granting them a “second or third life.”

This process not only preserves critical resources, such as rare earth metals, but also significantly reduces the energy required compared to producing new devices. The reballing technique exemplifies how Bestyield turns Mottainai into a practical, impactful strategy, aligning technological innovation with environmental stewardship.

Circular Economy: A Four-Loop Framework for Sustainability

Bestyield’s business model is built on the principles of the circular economy, a system designed to eliminate waste and promote the continual use of resources.

The company’s strategy is structured around four interconnected loops, each contributing to a sustainable ecosystem that benefits the company, its clients, and the environment:

- Sell or Lease Devices: Bestyield offers enterprises the flexibility to purchase or lease equipment for an average of five years, tailored to the dynamic needs of modern data centers. This approach ensures that high-quality technology is accessible without the need for constant replacements.

- Redistribution After Use: When devices reach the end of their primary use, Bestyield redistributes them to charities, schools, and non-governmental organizations (NGOs). This initiative democratizes access to technology, enabling underserved communities to benefit from high-quality devices.

- Collection and Component Recycling: Bestyield reclaims devices for refurbishment or “cannibalization,” where functional components are reused in other products. With over six direct stores in Taiwan and 100 franchise outlets globally, the company achieves a remarkable 99% utilization rate, ensuring that nearly every device is repurposed effectively.

- Final Recycling: For components that cannot be reused, Bestyield ensures proper recycling, minimizing environmental impact and adhering to strict sustainability standards.

To overcome consumer skepticism about refurbished products—a common barrier due to concerns about quality and reliability—Bestyield developed a blockchain-based “Quality Assurance” platform. This innovative system records every step of the repair process, from diagnostics to final testing, and stores the data in a secure, transparent database. Customers can scan a QR code to access a device’s repair history, test results, and certification details, fostering trust and transparency. This platform is particularly impactful for Apple products, such as iPhones and MacBooks, which are repaired using genuine tools and parts, ensuring performance comparable to new devices.

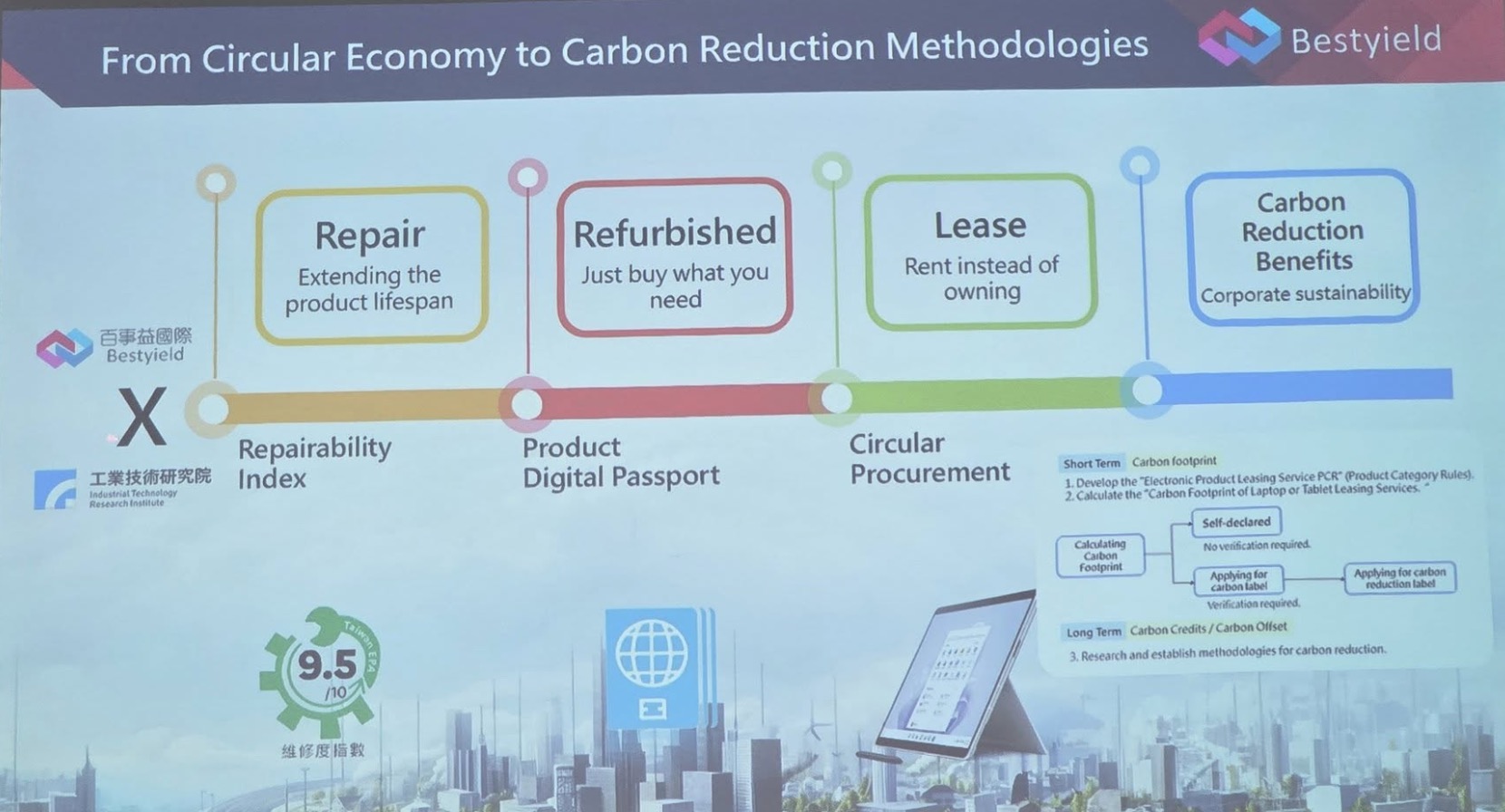

Environmental Impact: Measurable Results and Recognition

Bestyield’s efforts have yielded tangible environmental benefits. By extending the lifecycle of 1 million motherboards, the company has reduced carbon emissions by 91,000 tons—equivalent to the annual emissions of 225,000 cars. This achievement underscores the power of repair and reuse in combating climate change. In collaboration with Taiwan’s Industrial Technology Research Institute (ITRI), Bestyield has developed a “Repairability Index” to assess how easily devices can be repaired, as well as a “Product Digital Passport” to track a device’s lifecycle from production to recycling. These tools enhance transparency and accountability in the circular economy.

Additionally, Bestyield is pioneering a “Circular Permits” platform and advanced methodologies to calculate carbon reductions from repair activities. For every 100 devices processed, the company restores 99, achieving near-100% resource utilization. These efforts have earned Bestyield recognition from multiple international organizations, cementing its reputation as a leader in sustainable technology.

Technological Innovation: Powering Green Data Centers

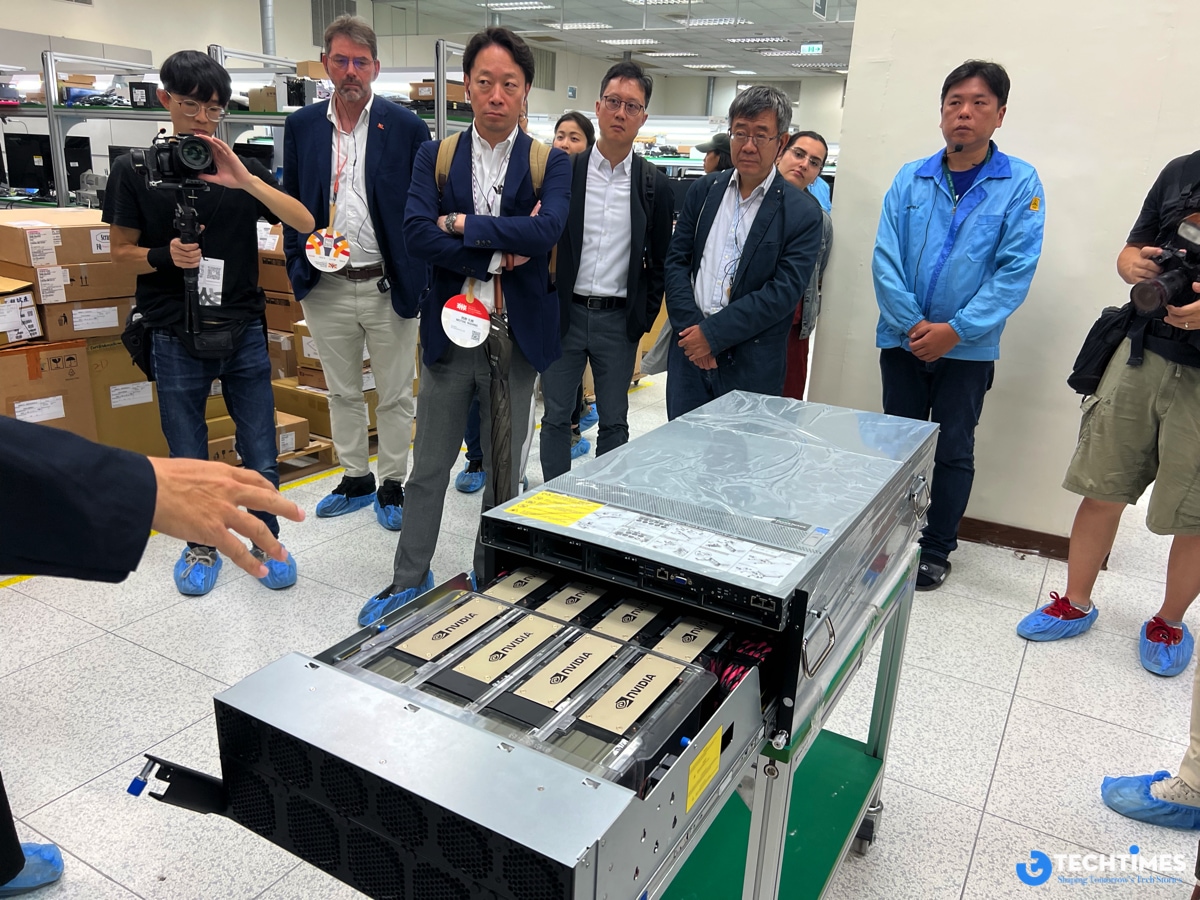

Bestyield’s contributions extend beyond repair to cutting-edge technological solutions for the digital age. The company’s Trinity 2.0 solution is a comprehensive, end-to-end system for data centers, covering everything from pre-sales planning to post-sales maintenance. A key innovation is the Cooling Distribution Unit (CDU), which leverages liquid cooling to dissipate heat from servers, GPUs, and CPUs. Compared to traditional air-cooling methods, the CDU is significantly more energy-efficient, reducing power consumption and aligning with the growing demand for green data centers.

The CDU’s ability to directly cool heat-generating components enhances performance while minimizing environmental impact. Developed in partnership with industry leaders, this technology positions Bestyield as a trailblazer in sustainable data center solutions. The company’s in-house software development further supports its operations, enabling customized solutions for internal systems and customer needs. With on-site services available at various service levels and a network of over 2,004 authorized service centers across 85 countries, Bestyield ensures seamless support for its clients worldwide.

The recent opening of a fully automated facility in Los Angeles, California, marks a significant milestone. Equipped with state-of-the-art automation and analytics, this site enhances Bestyield’s capabilities in smart manufacturing and repair, setting a new standard for efficiency and sustainability in the industry.

A Call to Action: Embracing the Smallest Circle

Bestyield is more than a repair company; it is a provider of a comprehensive ecosystem that drives fair value exchange in a collaborative era. The Mottainai philosophy reminds us that the smallest circle—using a product for its intended purpose as long as possible—has the most significant impact on preserving resources and protecting the planet. Before upgrading to the latest iPhone or laptop, consider the question: “Can I repair or pass it on to someone else?”

With accolades from numerous international organizations, Bestyield demonstrates that the circular economy is not a theoretical concept but a practical, scalable reality. As a subsidiary of Gigabyte, the company is paving the way for a sustainable future in the tech industry, inspiring individuals and businesses alike to join the “smallest circle.” By choosing repair over replacement, we can all embrace Mottainai—not just to save resources, but to safeguard the planet for future generations.